Turbochargers

The role of the turbocharger is to increase the pressure and density of the air supplied to the engine’s combustion process, resulting in more power, cleaner emissions, and improved engine torque.

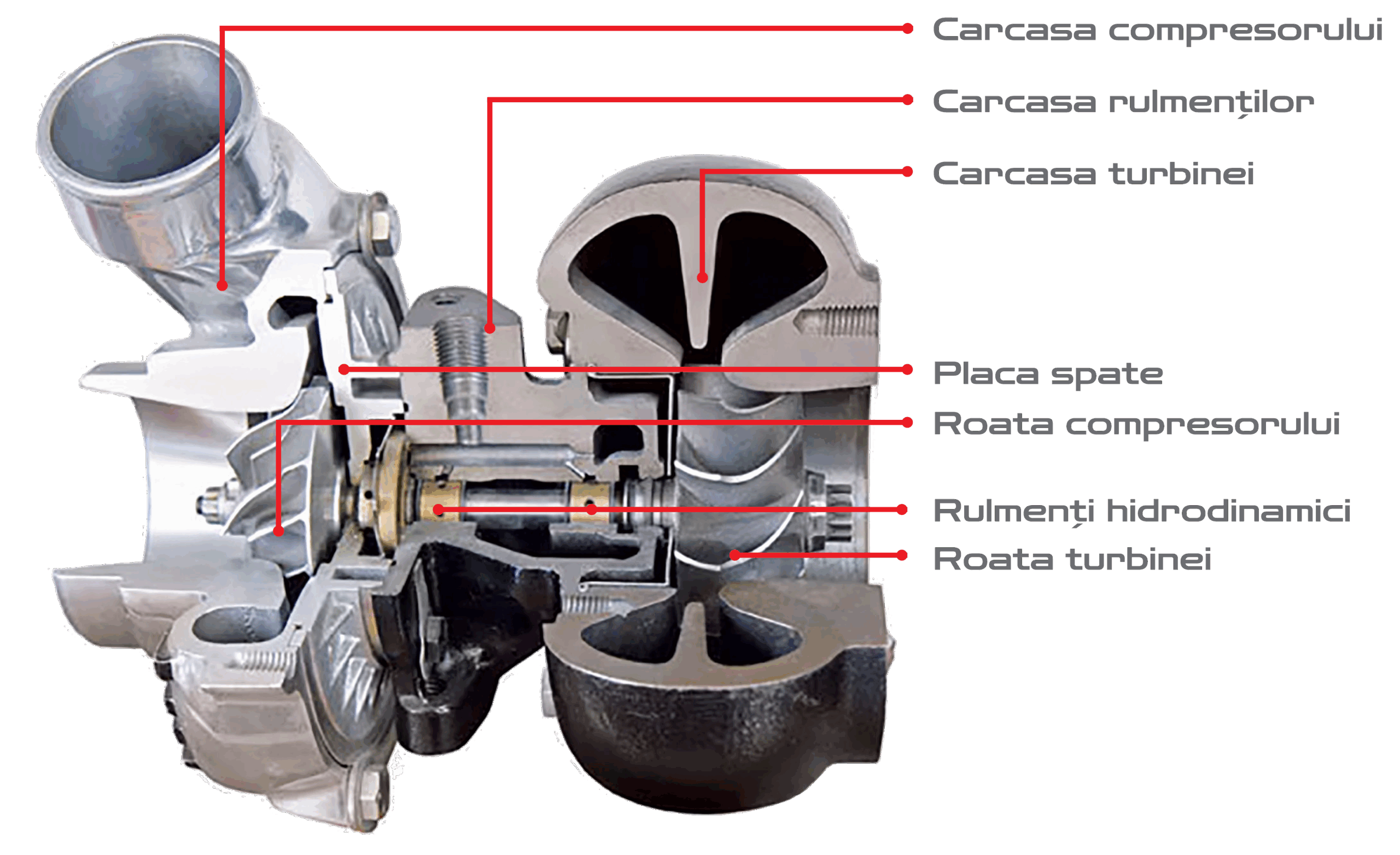

Main components

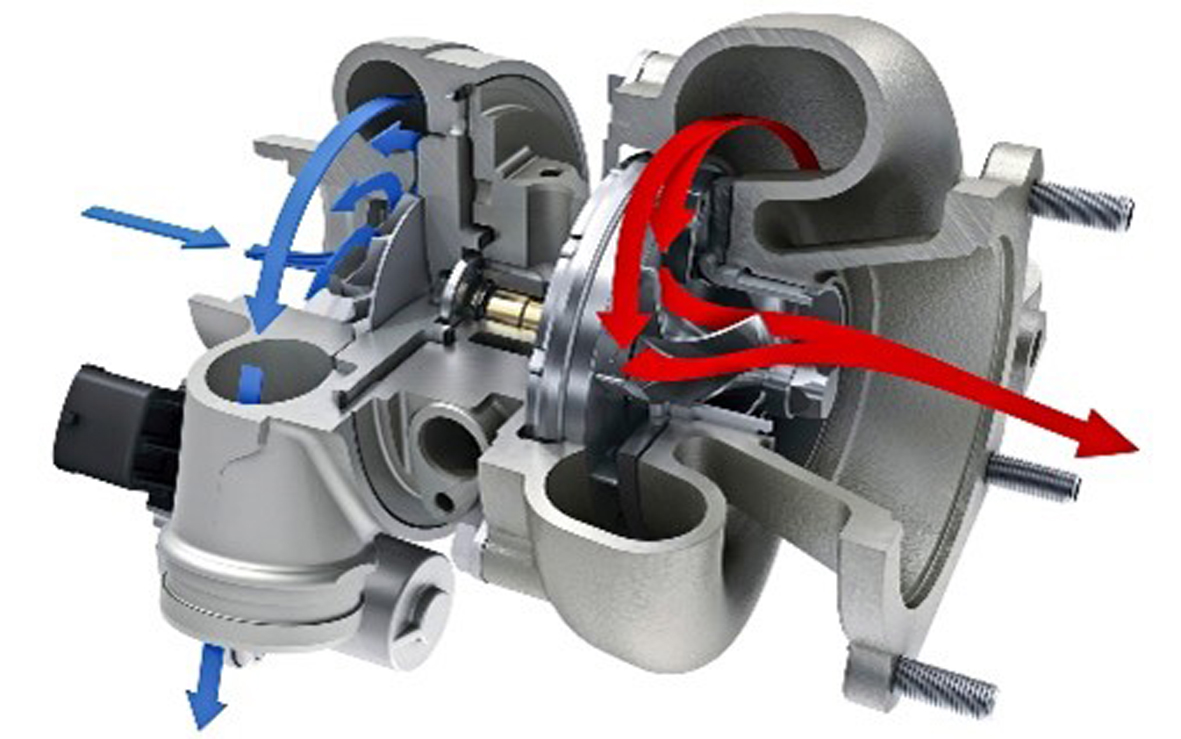

Mode of operation

On the turbine side, the exhaust gases drive the blades, causing the shaft to rotate at extremely high speeds, up to 300,000 revolutions per minute or 5,000 revolutions per second. On the compressor side, at the same speed, the shaft drives the blades that draw in outside air, accelerate it, compress it, and send it to the engine.

A turbocharger can operate for a long time if three vital rules are followed:

Clean and efficiently filtered oil. Oil and filter change intervals of 10,000 km. Oil contaminated with impurities grinds and erodes the central shaft, leading to excessive axial play that can no longer be controlled, resulting in shaft breakage.

Intake air filtered, free of impurities and blockages.

Exhaust gases free of oil contamination and blockages. Pressure differences caused by a clogged DPF lead to oil leaks in the turbocharger circuit.